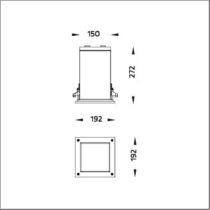

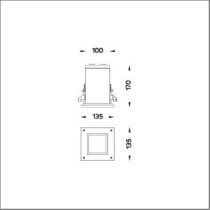

Specification

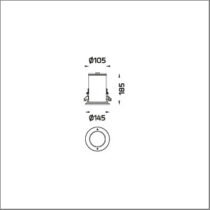

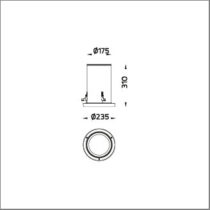

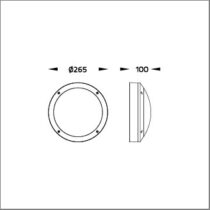

Inground uplight, IP67, Class I

– High-pressure Die Cast Aluminium alloy body and components.

– Extruded Aluminium S6063 alloy body with low copper content.

– Coating Process Nano Ceramic surface conversion, resistant to corrosive environment.

– Luminiare primarily coated with epoxy resin and top coated with UV

stabilized polyester powder and cured in digital temperature controlled chamber at 200°C.

– Impact resistant safety tempered glass cover. Able to withstand the temperature up to 250°C.

– Glass flushes to the front cover, no accumulation of dust and water.

– Molded PC lens from renowned manufacturers in various light distribution patterns.

– Weather resistant silicone gasket. Working temperature -40°C to +200°C.

– External screws are in stainless steel with protection dipping.

– High efficiency LED module utilized Philips Lumiled chips. Assembled on MCPCB and mounted on to heat conductive material.

– The whole systems tested to be operated under maximum ambient environment up to +40°C.

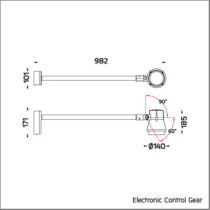

– High quality constant current LED driver. Conform to safety standard and electromagnetic compatibility standard.

– Tinned copper conductor with silicone insulated internal wire from ENCO or equivalents. IMQ approved. Working temperature -40°C to +180°C.

– Terminal Block/ Connector Class1 luminaire provided with the earth connection.

– Pre-wired cable Pre-wired with 3×1.0mm. H07RN-F neoprene cable from Aristoncavi or equivalents. IMQ approved.

– Equipped with anti-humidity kit.

– Installation work has to be carried on according to the enclosed installation manual.

– The water drainage system must be tested to ensure that it is sufficiency and efficiency.